Timber Buildings at COP26

Hester popped down to the Construction Scotland Innovation Centre (CSIC) for Wood for Good’s COP26 conference. Here she saw some of the timber solutions that are transforming the construction industry.

As part of the Glasgow COP26, the Construction Scotland Innovation Centre hosted a show and tell of all the up-and-coming ways that wood is being incorporated into buildings across the world. This blog is a rattle though some of the exciting things I saw; things that, corny though it is, give me optimism for the future. Onwards…

Wood offers a tangible route to building Net Zero homes and offices. When trees grow, they absorb carbon dioxide from the atmosphere, storing carbon in their trunks and the soil; homes and furniture built from wood continue to store this carbon. They also use a lot less brick, steel and concrete, whose production processes are responsible for significant carbon emissions steel and concrete account for 8% of global CO2 emissions). Meanwhile, in the forest, new trees replace those that have been cut, renewing the carbon stored in the forest. Of course, this isn’st a given, as where the wood is coming from, and how that forest is managed are critical, not just for carbon but for social justice, biodiversity, water quality and so much more. However, beyond certification, information about the source forest, or often even where your wood comes from is hard to find.

On arrival at CSIC I brightened at talk of a coffee van. Here I met Scott Francisco, founder and Director of Cities4Forests who, several coffees in, captivated me with their currents efforts to support the sustainable management of forests. With a focus on engaging citizens, their global platform advises cities of the benefits of connecting, investing and sourcing from forests to support their conservation and management.

Scott Francisco talking from his truck

Scott Francisco talking from his truck Scott Francisco talking from his truck which served up delicious food and drinks sourced directly from tropical forest communities on the front lines of conservation. The cappuccino from Cloud Forest Coffee was a particular favourite.

Globally deforestation and forest degradation accounts for ~11% of carbon emissions. Most deforestation is due to conversion of forests into agricultural land. Sustainable forestry provides an alternative source of income and therefore an incentive to maintain the forest whilst also supporting the social benefits, biodiversity and carbon storage. One successful example of this is Cities4Forests’ partner forest: Uaxactún Village and Community Forest Concession, in Guatemala. Here the wood is harvested by the local communities at a rate of one tree per acre every 40 years, providing income whilst keeping the rate of deforestation nearly at zero for over 25 years. A rare success story in a region with high rates of deforestation. Timber from this concession will be used to replace the boardwalk of the Brooklyn Bridge Promenade and build an alliance between citizens of New York and the community of Uaxactún.

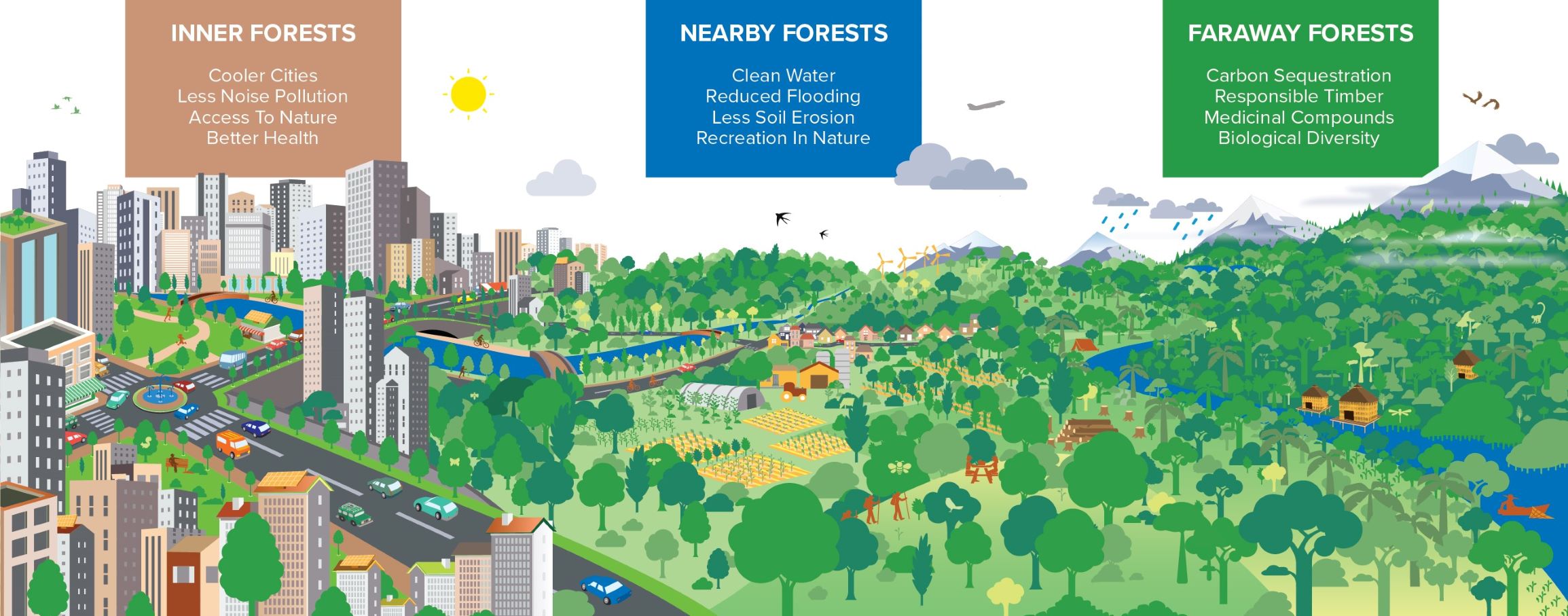

Cities4forests' three forest categories: Inner, Nearby and Faraway

Cities4forests' three forest categories: Inner, Nearby and Faraway Cities4forests’ three forest categories: Inner, Nearby and Faraway and their associated benefits for cities. CloudForest, of course, would add “Responsible Timber” as a desirable benefit from Inner and Nearby forests as well as Faraway forests.

Inside, CSIC was a bustle of live projects, with sawdust still on the floor, this was innovation in action. I saw a prototype GenZero classroom; a research and development project led by the Department of Education. This project aim is to deliver new schools with Net Zero emissions and improve the physical and mental wellbeing of pupils and staff. Historically government-procured schools have been designed and built to an agreed capital budget, at the expense of running costs and other value considerations. This project leads a much-needed shift to account for whole-life performance of the building, changing both procurement processes and design rules. The project has developed a new standardised design that uses offsite construction to build a Net Zero building through the efficient use of wood.

Prototype classroom

Prototype classroom  Cross-section through a GenZero wall

Cross-section through a GenZero wall Cross-section through a GenZero wall: structural cross laminated timber and glue laminated timber, followed by wood fibre insulation, water-proof membrane, and timber cladding.

If anyone was in doubt about the ability of home-grown timber to be used in construction, then experiencing the Transforming Timber prototype home, built from Scottish engineered timber, would set them straight. A collaboration between CSIC, Edinburgh Napier University, Edinburgh University, SNRG, Ecosystems Technologies and BSW, this prototype, and the wider project, will provide the evidence and business case to move the use of home-grown engineered timber into mainstream use. With the acquisition of BSW by Binderholz, a global producer of cross laminated timber, and their expectation to invest capital to broaden BSW’s UK capabilities, perhaps we will see mass production of home grown Cross Laminated Timber soon. Cross laminated timber, glue laminated timber, offsite construction all fall under “Modern Methods of Construction”. This interesting area deserves a blog post of its own so… watch this space!

Within CSIC there was a huge host of other innovative solutions: bricks made from recycled materials, construction robots, and power assist suits – not as exciting as a jet pack but refreshingly, a small size was available. The thing I was particularly happy to see in the flesh were LIGNOLOC wooden nails. Having spent lockdown painstakingly removing bent and rusty screws and nails from a rotten deck I very much hope to see their rapid proliferation. The nails are made from compressed beech wood that is impregnated with a resin. Rated for structural use, they are pneumatically driven into the wood, the heat created during this process leads the lignin in the nail to weld to the surrounding wood. They can also be driven in with a hammer but the same bond strength is not achieved, unless you’re Thor presumably.

Getting more home-grown wood into construction is something we are passionate about at CloudForest. So, if you have a project that needs some wood… check out our listings. We are continuing to develop additional features, so let us know if there’s something bespoke our platform could support.